We live in a digital world. Even before the COVID-19 pandemic, most of us were routinely shopping, banking, paying taxes, booking appointments, organising our schedules, communicating, networking, keeping business records, and even holding meetings using online and digital tools. ‘Making Tax Digital’ even sees digital transformation for businesses enshrined in UK law.

With lockdowns, stay-at-home orders and travel restrictions, businesses and individuals alike became reliant on digital connections in order to work, to talk or ‘meet’ with people remotely, to provide or seek customer support, and to buy or sell goods and services.

Accelerating digital transformation is arguably one of the silver linings of the crisis, opening the world up to consumers and businesses alike. The world has never been more connected, and it’s likely that many will want to keep the digital conveniences they’ve become accustomed to.

Manufacturing is slowly but surely embracing digital transformation, but even in companies where digitisation has been introduced, significant ‘silos’ of information and data remain. These prevent Original Equipment Manufacturers (OEMs) in particular from using their information – digital and analogue alike – in a joined up and cohesive way.

Fractured parts data drives OEM customers away

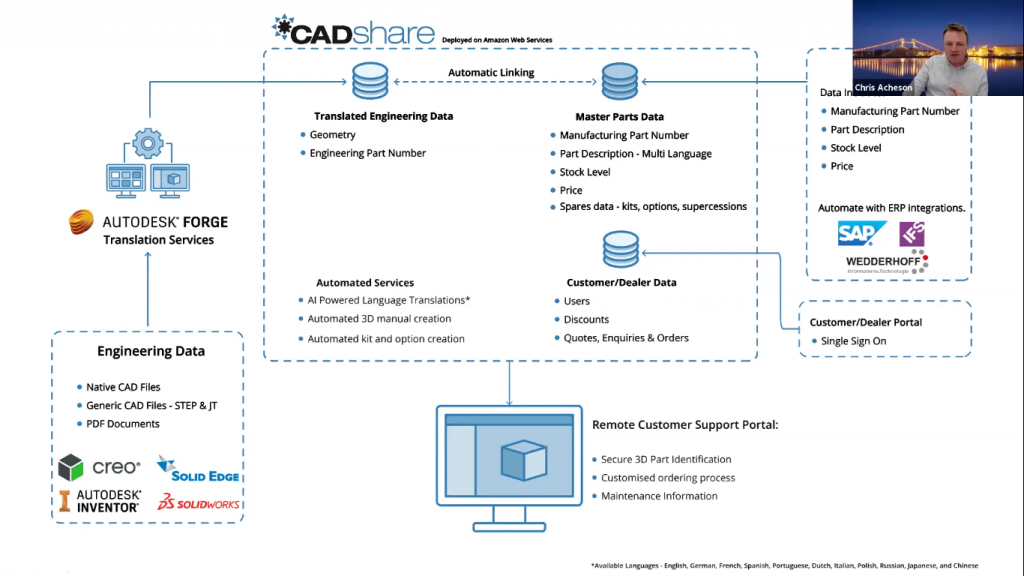

Many OEMs have parts data spread across CAD, ERP (Enterprise Resource Planning) and PLM (Product Lifecycle Management) systems. 2D parts catalogues are cobbled together from this information, which can be inaccurate and quickly go out of date as new models and specifications are added.

Aftermarket services are therefore delivered in a labour-intensive way, often involving numerous phone calls and emails between customers and aftermarket team members just to identify a part. Blurry photographs, sketchy descriptions, miscommunication and plain old human error can mean the process doesn’t just take a long time, it often leads to misidentification and the wrong part(s) being delivered.

When your customer is relying on a quick, reliable parts service to maintain productive uptime, there’s a real risk that this type of friction will force them to source parts elsewhere. Secondary manufacturers may offer a lower quality product, but an inferior product in their hand today is worth more to them than a part your aftermarket team takes a week just to identify.

Online parts sales could grow to 30% by 2035

According to research by McKinsey and Company in 2017, “about half of [aftermarket] revenues comes from wear-and-tear parts”. This proves that parts are a crucial element in increasing revenue and profits, boosting customer satisfaction, and building brand loyalty.

The report goes on to predict that “the e-commerce share of parts sales will increase to 20 to 30% by 2035”.

One of the report’s authors states that selling parts online “could be an opportunity for OEMs to start their own online presence or partner with successful platforms”. Today’s customer is digitally-savvy, which gives them huge control in the buying process – they are able to price, source and obtain products from a wide variety of sources – usually at the touch of a button.

The report concludes that “a digital sales model may be the key to a shorter, leaner value chain that benefits OEMs. By eliminating the need for intermediaries and streamlining the distributor layer, OEMs may see bigger margins and savings they may decide to pass on to their customers”.

How good e-commerce keeps customers happy and loyal

True digital transformation isn’t change for the sake of change. It’s about creating online customer portals that are easy to access and use, and make your business easier to buy from.

A self-service digital platform allows your customers to find exactly what they need, at whatever time of day they happen to need it, and create an order then and there. Bringing all of your analogue and digital design data into one place frees up your aftermarket staff to use their specialised skills more productively.

Instead of emails and phone calls pinging back and forth, your customer could log on to their customer portal, identify the part(s) they need by selecting one of native CAD model(s) in the live viewer, and complete the order. Indeed, this could all happen while sales and aftermarket staff are tucked up in their beds at night! E-commerce allows orders to be generated round the clock, not just during office hours and local time. This helps OEMs to serve international markets more easily.

Cloud-based systems also allow OEMs to quickly and easily update data with new equipment and specs.

As well as being able to order directly from OEMs on a regular basis, customers can keep track of previous orders within an online ordering system, making reordering and tracking quick and easy. Offering a seamless, friction-free parts ordering process on top of the superior parts quality is a solid plan for future-proofing an OEM business against competition from cheap imports and secondary manufacturers.

Digital transformation has been rapidly accelerated by world events, and it is here to stay. Virtually every industry on the planet is using digital, online and cloud-based systems and portals to connect with, support, and sell to their customers.

The modern consumer resents any unnecessary effort in locating and buying what they need – and this is true within engineering and manufacturing sectors too. Bringing existing systems, ERP, PLMs, CAD data, and analogue information together into a single, cloud-based source of truth makes customers happy and loyal, staff more productive and less frustrated, and leads to more sales and higher profit margins. That’s a win, win, win situation!

To learn more about how CADshare can streamline your Aftermarket parts service – click here to book a live demo.